ADVANTAGES OF MANUFACTURING TOWING HOOKS IN ADI RATHER THAN CONVENTIONAL STEEL

WHAT IS AUSTEMPERED DUCTILE IRON (ADI)?

Austempered Ductile Iron (ADI) is a type of ductile iron that undergoes a specialized heat treatment process known as austempering. This process involves heating the iron to a high temperature and then rapidly cooling it in a salt bath. The result is a material with an exceptional combination of strength, toughness, and wear resistance, making it an ideal candidate for various high-performance applications.

ENHANCED MECHANICAL PROPERTIES

One of the primary advantages of ADI over conventional steel is its superior mechanical properties. ADI exhibits a unique microstructure, consisting of ausferrite, which imparts a remarkable combination of high strength and ductility. This combination is particularly beneficial for towing hooks, which must withstand significant loads and stresses without deforming or breaking.

Strength and Toughness: ADI offers a higher tensile strength compared to conventional steel, often reaching values of up to 1400 MPa. Additionally, it maintains excellent toughness, allowing the towing hook to absorb impact energy without fracturing. This makes ADI towing hooks more reliable and safer in demanding conditions.

Fatigue Resistance: Towing hooks are subjected to cyclic loading during their service life, which can lead to fatigue failure. ADI demonstrates superior fatigue resistance compared to conventional steel, enhancing the longevity and durability of the towing hooks.

WEIGHT REDUCTION AND FUEL EFFICIENCY

In the automotive industry, weight reduction is a critical factor in improving fuel efficiency and reducing emissions. ADI offers a significant advantage in this regard due to its high strength-to-weight ratio. By manufacturing towing hooks in ADI, it is possible to reduce the component's weight without compromising its performance.

Material Density: ADI has a lower density compared to conventional steel, which translates into lighter towing hooks. This weight reduction contributes to an overall decrease in the vehicle's weight, resulting in improved fuel efficiency and lower carbon emissions.

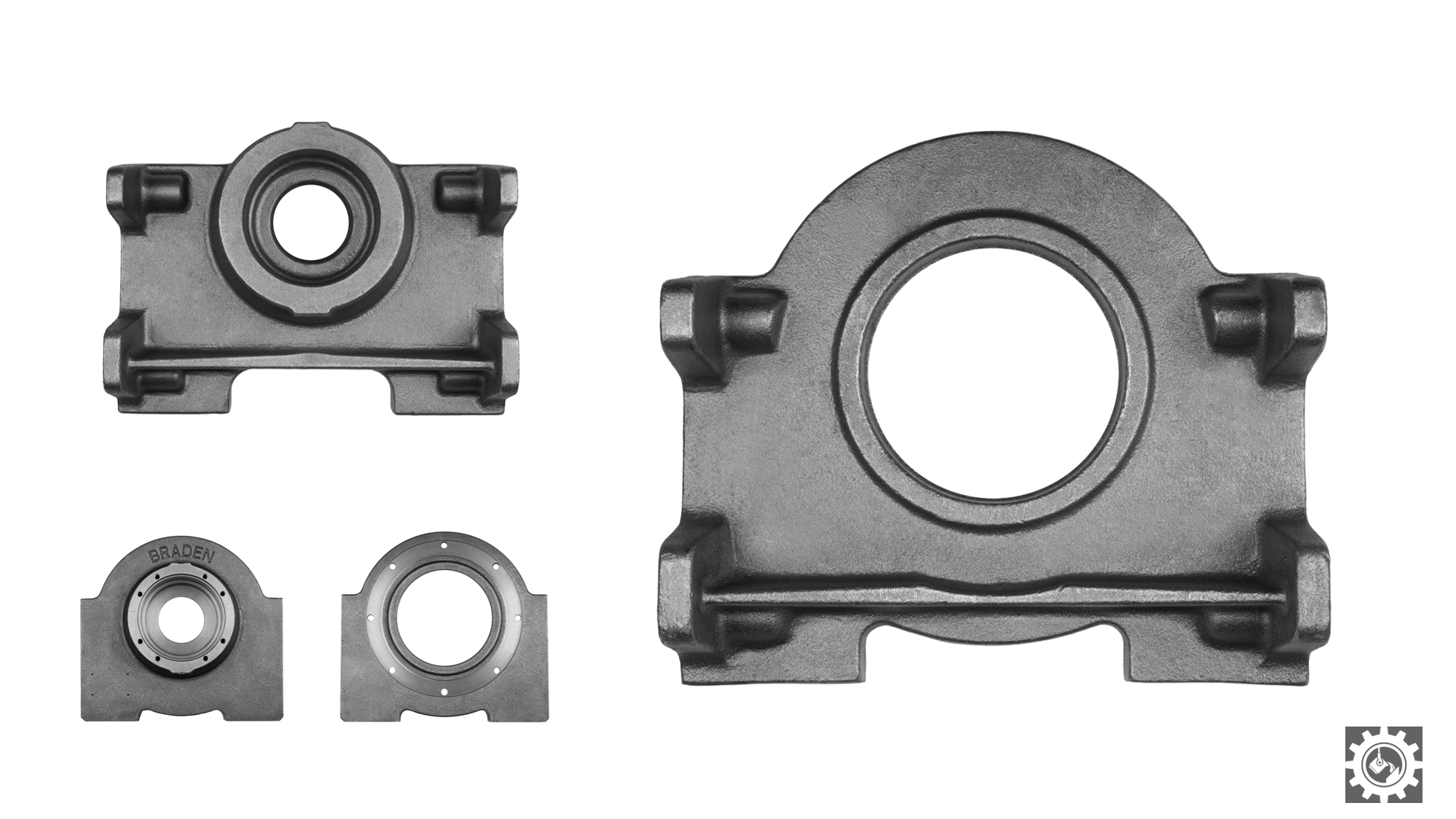

Design Flexibility: The superior mechanical properties of ADI allow for more innovative and efficient designs. Engineers can create towing hooks with optimized geometries that use less material while maintaining the required strength and durability. This design flexibility further contributes to weight reduction and performance enhancement.

COST-EFFECTIVENESS AND MANUFACTURING EFFICIENCY

Cost considerations are always paramount in manufacturing decisions. ADI presents several cost advantages over conventional steel, making it an attractive choice for towing hook production.

Material Costs: While the initial cost of ADI may be slightly higher than conventional steel, the overall cost savings can be substantial. ADI's enhanced durability and wear resistance reduce the need for frequent replacements and maintenance, resulting in long-term cost savings.

Manufacturing Process: The austempering process used to produce ADI is relatively straightforward and can be integrated into existing manufacturing setups with minimal modifications. This compatibility with current production lines reduces the need for significant capital investment and allows for efficient and cost-effective manufacturing.

Machinability: ADI is known for its excellent machinability, making it easier to shape and finish compared to conventional steel. This ease of machining reduces production time and labor costs, further enhancing the cost-effectiveness of ADI towing hooks.

IMPROVED WEAR AND CORROSION RESISTANCE

Towing hooks are often exposed to harsh environmental conditions, including moisture, dirt, and road salt, which can lead to wear and corrosion. ADI's superior wear and corrosion resistance make it a more robust choice for towing hook applications.

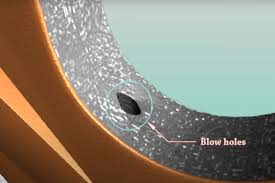

Wear Resistance: The ausferritic microstructure of ADI imparts excellent wear resistance, allowing towing hooks to maintain their performance and structural integrity even after prolonged use. This reduces the frequency of replacements and ensures consistent performance.

Corrosion Resistance: ADI's corrosion resistance is superior to that of conventional steel, particularly in aggressive environments. This resistance to corrosion extends the lifespan of towing hooks and reduces the risk of failure due to rust and degradation.

ENVIRONMENTAL BENEFITS

In addition to the performance and economic advantages, ADI also offers environmental benefits. The production of ADI generates less greenhouse gas emissions compared to conventional steel manufacturing. The reduced weight of ADI towing hooks contributes to improved fuel efficiency, leading to lower emissions during the vehicle's operational life. By choosing ADI over conventional steel, manufacturers can contribute to a more sustainable and environmentally friendly automotive industry.

CONCLUSION

The advantages of manufacturing towing hooks in Austempered Ductile Iron (ADI) over conventional steel are clear. ADI's superior mechanical properties, weight reduction benefits, cost-effectiveness, improved wear and corrosion resistance, and environmental advantages make it the material of choice for high-performance towing hooks. As the automotive industry continues to evolve, embracing advanced materials like ADI will be crucial in meeting the demands for safer, more efficient, and sustainable vehicles. By leveraging the benefits of ADI, manufacturers can enhance the performance and reliability of towing hooks, ultimately delivering better products to consumers.